Articles by George Schuetz

Quality 101

Even a digital caliper — which takes most of the guesswork out of reading the measured value — still requires skill to correctly apply it to the measured dimension.

Read More

Air Gaging Moving Forward Faster Than You Think

Let's look at how air tooling and its accessories are moving into today's modern manufacturing processes.

July 27, 2023

Diameter Measurement

How to Measure Big IDs and ODs

As with any diameter measurement, there are several possible solutions.

June 7, 2023

Measurement

Handheld Gaging: It All Comes Down To The Touch

Combining the best of metrology and other industries creates products that are simple for the operator to use while also providing very complex measuring results.

September 1, 2022

Measurement

It is Never Too Late to Teach an Old Custom Gage New Tricks

There are myriad ways to breathe new life into existing gages without the need to invest in new gaging.

March 8, 2022

Measurement

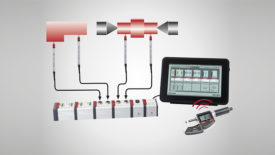

Modern Gaging Trends: Technology Evolves to Meet the Needs of Today’s User

Implementing these new technologies will make today's gages easier to use, offer more capabilities in an easier-to-read fashion and survive point of manufacture gaging.

September 1, 2021

Striving to New Heights

Today's height gages are feature-packed, high-performance measuring systems.

September 30, 2020

Benefits of Automating the Calibration Process

As with any measurement process, reducing the influence of the human element helps improve the results and reduce the measurement uncertainty.

August 3, 2020

Calibrating Standard Threaded Gages

Applications requiring threaded parts come with a variety of performance requirements.

May 1, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing