In engineering and manufacturing, anomalies often emerge, ranging from material imperfections to unexpected component behaviors. These deviations, which can critically impact product performance or safety, transform into intricate puzzles. Navigating these complexities underscores the profound significance of the nondestructive testing (NDT) discipline, a method designed to identify and address these very challenges without compromising the integrity of the subject under examination. Such was my experience when a leading American racecar component manufacturer raised a seemingly perplexing concern: the suspected presence of tungsten within their titanium push rods.

For anyone familiar with the science of metals, the very thought is counterintuitive. Tungsten and titanium have markedly different densities, melting points and unique profiles. If tungsten was present in titanium push rods, engine failure was not far behind. Yet, the essence of NDT lies in diving deep without causing disruption, making it the optimal approach for addressing such a challenge.

While many other labs may have opted for a somewhat destructive manner of determining the composition of these push rods, my testing lab chose radiography, a valuable NDT method. Radiography’s unique capability lies in examining materials without the slightest alteration of their physical state. This non-invasive approach is particularly important when dealing with components such as push rods, where maintaining structural integrity directly translates to optimal performance. Traditional testing methods were clearly off the table as they would have required invasive and destructive techniques to determine the issue with these push rods.

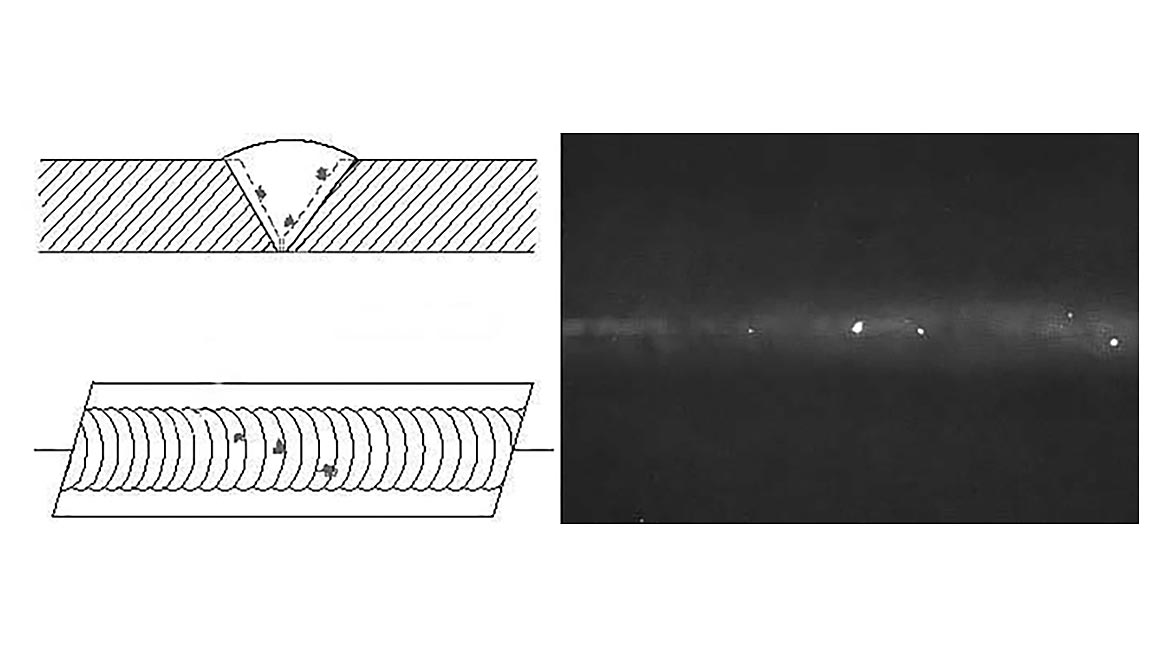

By using X-rays or gamma rays, radiographic NDT can clearly see into an object’s internal structure. The resulting image, captured on a detector or film, reveals material composition based on density variations. Consequently, for the push rods in question, the presence of tungsten—a material far denser than titanium—would manifest as a distinctive contrast on the radiograph. The push rods containing tungsten could then be sequestered from those that remained pure titanium, ensuring that the largest possible number of billets could be deployed.

The application of this radiographic process produced a revelation. The films displayed a stark white indication, a clear testament to tungsten’s presence in the titanium rods. What had initially seemed improbable was now an incontrovertible truth.

Tungsten inclusions. Tungsten is a brittle and inherently dense material used in the electrode in tungsten inert gas welding. If improper welding procedures are used, tungsten may be entrapped in the weld. Radiographically, tungsten is more dense than aluminum or steel, therefore it shows up as a lighter area with a distinct outline on the radiograph.

https://www.nde-ed.org/NDETechniques/Radiography/TechCalibrations/RadiographInterp.xhtml

The puzzle wasn’t solved by detection alone. The subsequent quest to trace the origins of this tungsten led to an intriguing historical connection. The titanium hulls of the Soviet-manufactured Akula class submarines became a prime suspect. During their construction, certain welding practices, notably gas tungsten arc welding (GTAW) had inadvertently introduced tungsten residues. As fate would have it, these hulls, when decommissioned, were recycled into titanium billets. The ineradicable tungsten then found its way into the newly cast push rods.

In such a scenario, the benefits to approaching this puzzle using NDT were numerous. It wasn’t just about detection but doing so without compromising the push rods’ integrity. Moreover, it offered a cost-effective, efficient, and clear method to identify and rectify the anomaly with 100 percent certainty. Absent NDT, this dilemma might have precipitated more invasive and less conclusive testing methods.

This case demonstrates the broader significance of NDT in today’s advanced manufacturing landscape. NDT is not merely about identifying inconsistencies; it’s about ensuring preservation. In a world characterized by intricate manufacturing processes and increasingly complex supply chains, NDT emerges not just as a method but as an irreplaceable cornerstone, underpinning quality, safety, and integrity.

The titanium-tungsten puzzle isn’t just a testament to the value of radiographic NDT, but also a reminder of the NDT’s ever-evolving relevance in shaping the future of manufacturing.

Source: Iowa State University, Center for Nondestructive Evaluation.