Manufacturing has evolved rapidly in the past decade. The Fourth Industrial Revolution is beginning to take hold, marked by the use of data and digitization to improve processes and create new revenue streams. Most manufacturers are aware of the benefits of digitalization and are in the process of implementing it. A recent Frost & Sullivan survey of 225 IT executives and other decisionmakers in the manufacturing industry showed that nearly all (99%) were at some stage of a digital transformation (DT) process. Manufacturing was the primary business process expected to be most impacted by DT (as opposed to sales or R&D, for example) and was noted by 74% of respondents.

Over half (53%) of respondents also stated that production output was their top way of measuring successful DT deployment. Accurately capturing, analyzing, and using data within the manufacturing process is at the heart of reaching these goals. Manufacturers want to expand how they get and use information across operations. Advanced metrology and the data it generates are being used in new and innovative ways by manufacturers looking to take the lead in their digital transformation goals.

INTEGRATING TEAMS AND FUNCTIONS FOR IMPROVED OUTCOMES

Traditionally, design and engineering have been conducted "over the wall" from the manufacturing processes. While this can help a team focus on core activities, it can also lead to conflicting goals within an organization. A design team aims to solve customer challenges and incorporate preferences; manufacturing typically seeks to control costs, increase throughput, and better utilize resources such as people, processes, equipment, and materials.

Leading manufacturers are working to lower the wall separating design and manufacturing, finding ways to create innovative and industry-leading products while also preserving the bottom line. Using design beyond product ideation and configuration is also important. Today, design teams help ensure the manufacturing process is optimized, from reverse engineering replacement parts in-house to improving an entire facility's workflow. Technologies such as advanced 3D metrology can facilitate reaching across silos and enable data-driven decisions.

HOW DATA IS DRIVING DESIGN PROCESS EVOLUTION

The design process is evolving, becoming more nimble and dynamic, and shortening the time it takes to go to market with new or updated products. Using data-driven approaches means that real-time feedback from customers and developments in the field can be more rapidly assessed and integrated. Data linking environment, utilization, and product features gathered from IoT devices inform these new iterations. Advanced, laser-enabled 3D metrology solutions create detailed and precise virtual models of products for an organization's quality and manufacturing functions. These digitized representations can also be used by design teams to virtually test and model new or updated products, catching potential faults and challenges before the prototyping and manufacturing phases. Advanced metrology-enhanced designs can be used by in-house or third-party design firms to increase their services' accuracy and speed and create value-added services.

For example, Diverse Dimensions is a full-service dimensional measurement and reverse engineering lab based in Michigan. The business recognized early that it could gain a competitive advantage and provide more value to its clients if it added insights such as root-cause analysis to its scanning and measurement services. Diverse Dimensions uses several of the FARO® scanning and measurement solutions to ensure accuracy and reduce measurement time over previous methods by up to 40%.

For instance, FARO's ScanArm can measure up to 1,200,000 points per second and provide highly detailed and accurate 3D point clouds that can be exported, analyzed immediately, and converted to CAD. This high level of precision, combined with the arm's articulation, enables it to thoroughly scan and compare items with intricate forms. For high-volume projects with less dimensional complexity, the system can adapt to complete the analysis even faster. Reducing measurement times also means repetitive jobs are less taxing for the operator.

Using data-driven approaches means that realtime feedback from customers and developments in the field can be more rapidly assessed and integrated. Data linking environment, utilization, and product features gathered from IoT devices inform these new iterations.

DESIGNING PRODUCTIVITY FROM PART TO PLANT

Design teams are often called upon to reverse engineer replacement parts used in manufacturing.

Reverse engineering and in-house component building can save a manufacturer the time and cost of using the original provider or third-party shop. Sophisticated metrology and analytics ensure that the replacements fit the current equipment based on wear and usage patterns, not on the original specs, which may no longer fit after years of use. It also accounts for any modifications that may have been made since the initial installation.

Internal process benefits of a strong design function can also go beyond repairing equipment. Entire factories and processing centers can be designed to improve the flow and throughput of processes. The first major step in digital transformation is not optimization but standardization: using modern and advanced metrology tools, entire plants can be laid out in 3D digital twins to test for

efficiency and optimization. They can then be replicated with other locations. Over time, continued monitoring of those plants and processes can then be fed back into the digital twin to determine how improvements in one location, or under certain circumstances, can be optimized across multiple sites.

For example, Volvo uses FARO technology to map out, optimize, and replicate entire factories. The company had the foresight and ingenuity to leverage advanced metrology beyond the typical product and component sphere. Using data from FARO's advanced metrology tools, Volvo can thoroughly scan, map, and analyze all of its global plants and use this data to create digital twins of the plants. This has been used to produce “carbon copies” of facilities to ease everything from process improvements to regulatory audits.

When new equipment needs to be installed, no one needs to travel to each place to implement it, as the specifications are maintained in the digital twin. Digitally driven, laser-enabled metrology on-site can confirm a perfect fit for the replacement and can directly upload any data and insights from the process into the digital twin to be leveraged for all the other plants in the system. Planning is done on the cloud, saving travel time and costs, reducing ambiguity, and even recognizing efficiencies of scale for frequently made improvements or repairs.

Items that need frequent repairs or updates can also be flagged, whether the repairs are needed across all locations or only a few. These inferences can help a manufacturer understand if the part or equipment configuration is faulty or if there are unusual circumstances in a particular location, such as a higher usage rate or otherwise unidentified power fluctuations.

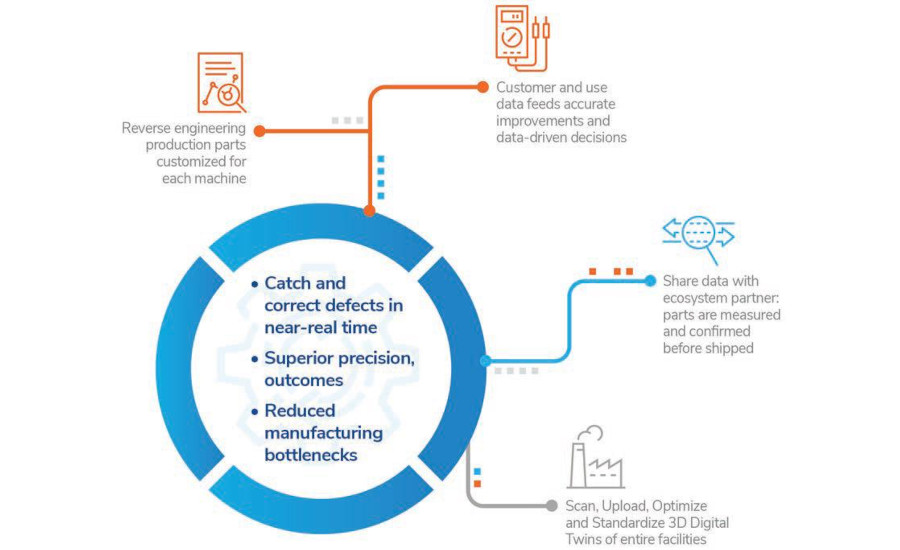

Chart 1 illustrates numerous applications where advanced metrology can inform and improve processes, including designing a product, optimizing a plant, and enabling better communication across an ecosystem. In the highly digital world of manufacturing, competitive advantage can only be gained with efficiencies in processes recognized across departments, not just within silos. Advanced, laser-enabled 3D metrology is one facet of this equation. However, it is critical because it is the only way to create an accurate digital representation of products and manufacturing processes necessary for data-driven decisions.

Chart 1: Metrology Enables Design to Improve Entire Process

Get in touch with a FARO representative to learn more here: www.faro.com