Home » Keywords: » electric vehicles

Items Tagged with 'electric vehicles'

ARTICLES

NDT | Leak Testing

Manufacturers that routinely challenge their leak tightness testing process will consistently produce products with reliable performance, battery longevity and safety.

Read More

Test & Inspection

New Noncontact Technologies Meet the Challenges of the Evolving Automotive Industry

The transition from ice to electric powertrain requires a complete review of the approach to quality and process controls.

December 28, 2023

Machine Vision Systems

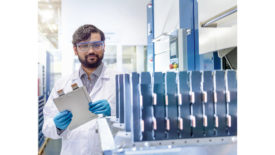

Machine Vision for Battery Production 4.0

Machine vision has increasingly established itself as an indispensable technology for companies in a wide range of industries.

November 13, 2023

Quality 101

GD&T for Electric Vehicles Supports Consistent Quality Control

GD&T allows engineers to define feature relationships, ensuring proper alignment and interchangeability.

October 17, 2023

NDT | Computed Tomography

Creating the Future of Mobility with CT Inspection of Batteries

Industrial x-ray and CT inspection supports quality control and failure analysis at all stages of a battery's lifecycle.

September 21, 2023

Test & Inspection

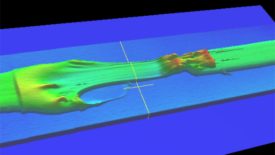

e-Powertrain Electric Motor Gear Train Simulated Testing with the Digital Twin

By replacing the initial tests with digital twin simulations, results can be obtained quickly, and at a much lower cost.

September 18, 2023

EV Battery Manufacturing: Steps to Assure Joining Quality and Eliminate Harmful Leaks

The importance of reliability in EV batteries is paramount to the overall vehicle performance.

July 13, 2023

Test & Inspection

Hardness Testing of Individual Battery Electrode Particulates

Recently, researchers have shown correlation between particle hardness and cycle performance.

April 4, 2023

Electric Vehicles

Leak-Detection Standards for Electric Vehicles Long Overdue

Quality control lags behind rapid growth of EV sales in North America.

October 3, 2022

NDT | Leak Testing

E-Mobility Gives Automakers a Host of Leak Detection Challenges

EV battery cells, battery packs, electric motors and other systems modified for EV applications all require leak testing to assure both quality and safety.

June 9, 2021

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing