Home » Keywords: » COVID-19

Items Tagged with 'COVID-19'

ARTICLES

Aerospace | AS9100

Before starting the revision, the writing team asked what was good, what was not so good, and what needed changing.

Read More

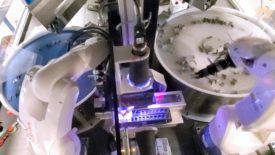

Management | Robotics

As Robotics Gain Hold, Here’s How to Manage Them

The pandemic has only fueled the worker shortage, prompting manufacturers to embrace automation in large numbers. Senior leadership can ensure robotics are implemented correctly.

June 1, 2023

Quality 101

Automation’s Growing Role in Universal Testing

The pandemic proved just how important universal testers are to quality. As staff shorages endure, automation is keeping this technology on point.

May 10, 2023

Vision & Sensors | Cameras

The Changing Face of Smart Cameras in Machine Vision

Beyond the growth in applications brought about by improvements in CMOS sensor technology, another significant trend is the increase in applications that extend beyond the visible spectrum.

March 16, 2023

NDT | Magnetic Particle Inspection

Magnetic Particle Inspection Is Here to Stay

While magnetic particle inspection techniques have stood the test of time, the equipment involved has seen updates to keep up with demand, experts say.

February 16, 2023

From the Editor | Darryl Seland

Knowledge is Power

From Sun Tzu to Chuck McGill.

January 12, 2023

Test & Inspection

How a Shrinking Workforce Affects Testing and Inspection in NDT

As the pandemic and advances in technology impact the field, education and training remain paramount — especially for newcomers.

December 30, 2022

The Spending Forecast is Here

The 22nd Annual Quality Spending Survey Results

Concerns about Covid-19 are down, but inflation worries are up.

December 29, 2022

Manufacturing Skills Gap

COVID Has Not Helped the Skills Gap

Training programs paused during the pandemic, but manufacturers are upping their game to attract workers.

November 1, 2022

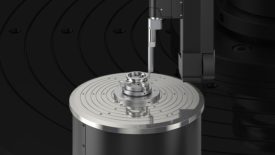

Measurement

Roundness Measurement Technology Drives Quality and Productivity

For certain parts and products, roundness measurement is a critical part of the quality assurance process.

August 1, 2022

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing