Home » Keywords: » Hexagon Manufacturing Intelligence

Items Tagged with 'Hexagon Manufacturing Intelligence'

ARTICLES

Quality Headline

Hexagon Announces HxGN LIVE Smart Manufacturing Detroit 2020

January 20, 2020

EVENTS

Webinar

3/14/24 to 3/14/25

Contact: Meg K.

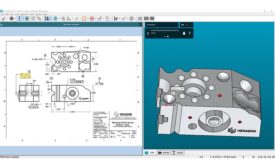

The Ride to Excellence: Embracing Digital Twins in Automotive Design, Development & Production

Webinar Sponsored Webinars Sponsored

4/18/24 to 4/18/25

Contact: Meg K.

Focus on What Matters: The Future of Digital Precision in Manufacturing

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing