Home » Keywords: » non destructive testing

Items Tagged with 'non destructive testing'

ARTICLES

ASNT Column | Muriel Magloire

NDT plays a major role in preventing disasters and upholding safety standards.

Read More

Test & Inspection

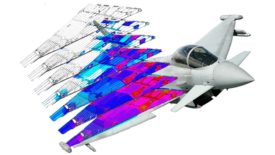

Phased array ultrasonic testing (PAUT)

Phased array ultrasonic inspection has become an indispensable tool in the aerospace industry, contributing to the safety and reliability of aircraft components.

December 31, 2023

Quality 101

Nondestructive Testing Using the Resonance Acoustic Method

RAM is a volumetric approach and evaluates the whole part, both for internal and external structural flaws, metallurgical deviations, and consistency.

December 15, 2022

NDT Trends

Nondestructive Testing (NDT) Trends

Manual means of performing NDT and human evaluation of the results is trending more and more to automated, digitized and artificial intelligence interpretation of the results whenever economically possible.

October 10, 2022

NDT | Ultrasonics

Automated Inspection of Wind Blades Using a Collaborative Robot

Improve the nondestructive inspection workflow using the latest technology.

April 1, 2022

How 3D Scanning Solution Boost Quality Gains and Productivity

The key to being successful with automated measuring solutions is to simplify the deployment.

November 9, 2021

Aerospace | NDT Service

Why Service Matters When Purchasing an NDT Inspection System

Selecting a service plan should go hand in hand with the system purchase.

July 1, 2021

From the Editor | Darryl Seland

Speaking the same language

Choosing your words and everything else, wisely.

March 5, 2021

Sponsored Content

Seeing is Believing: 2D and 3D X-ray Technologies for Nondestructive Testing

July 1, 2019

EVENTS

Industry Featured Event

5/1/24 to 5/2/24

Music City Center

201 Rep. John Lewis Way S

Nashville, TN

United States

The Quality Show South

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing