Home » Keywords: » automated inspection

Items Tagged with 'automated inspection'

ARTICLES

Aerospace | NDT in Aerospace

The looping of CT analysis via digital models can improve every aspect of the design-to-production cycle.

Read More

Vision & Sensors | Machine Vision 101

Automated Inspection 101: Benefits for Industry

Automated inspection can take many forms and show up in a wide variety of industries.

July 4, 2023

How Automation Helps to Improve Quality

Automating quality control can look different for every organization.

December 10, 2021

VISION GUIDED ROBOTICS

Best Practices for Implementing Vision Guided Robotics

An important first step in any application is a thorough project evaluation prior to system design and implementation.

April 8, 2021

Save Time with Auto Ballooning

By auto ballooning various model types, companies can complete forms faster.

June 1, 2020

Quality in Automation > Trends

The Latest Trends on the Shop Floor

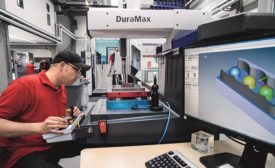

Automation has made closed-loop metrology systems, nondestructive testing and productivity increasingly accessible.

April 6, 2020

Machine Vision: Inspecting Reflective Surfaces with Deflectometry

Reliable detection of even the tiniest scratches.

December 5, 2019

Fully Leveraging Machine Uptime

Offset measurements away from the machine tool boost manufacturing efficiency.

November 5, 2019

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing