Home » Keywords: » training

Items Tagged with 'training'

ARTICLES

NDT | Training

Where does the bulk of NDT training responsibility lie, in the classroom or in the field?

Read More

Quality Headline

Manufacturing Institute Releases Report on Transitioning Military-Affiliated Talent into Manufacturing

February 13, 2024

Standards 101 | Roderick A. Munro

Training Auditors to Integrated MSS Requirements

There are a few things that could be useful in your internal training program.

January 29, 2024

Column | Lara Threet

Teaching Quality in Higher Education

With the importance of quality in manufacturing, how do we prepare the future workforce for the field?

December 18, 2023

Management

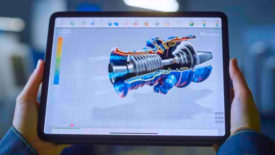

A Machine Trainer: Safe and efficient shop floor training management

Learn more about CNC and CMM machine trainer simulators.

October 23, 2023

NDT | Training

Focus on the Training Quality

Industry veteran Charles Hellier discusses how to improve training within NDT.

October 9, 2023

Sponsored Content

eBook | How to Prepare for a Successful 3D Work Instruction Pilot

June 9, 2023

NDT | Training

The Need for Excellence in NDT Training

The technology of NDT deserves and requires excellence in training programs.

November 7, 2022

EVENTS

Webinar

10/18/23 to 10/18/24

Contact: Meg K.

Cut Training Time and Improve Quality With Interactive Digital Work Instructions

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing