Home » Keywords: » reverse engineering software

Items Tagged with 'reverse engineering software'

ARTICLES

Software & Analysis

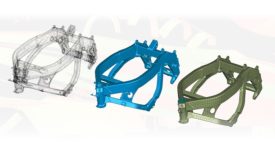

Reverse Engineering Software For 3D

Once the model has been generated, you can use the software to analyze the model.

June 6, 2023

Software & Analysis

Reverse Engineering Software: Who? What? When? Where? Why?

Reverse engineering is used practically everywhere and in every industry.

September 1, 2022

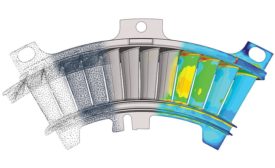

Quality Control With 3D Scanning

3D scanners are quick, accurate and record mass amounts of geometry, making them less laborious and more flexible than basic metrology tools.

January 3, 2022

Software & Analysis

Practical Reverse Engineering

Choosing the right tools for the job.

December 6, 2021

Reverse Engineering Software 101

It is the process of converting a physical part into a digital form.

May 1, 2020

Reverse Engineering for a Model-Based World

The list of reverse engineering applications is long and will continue to grow as engineers create new and creative ways to use the technology.

November 1, 2019

Reverse Engineering: A Basic How-To

The advancements in technology over the last 20 years have been amazing.

June 1, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing