Home » Keywords: » 3D scanning

Items Tagged with '3D scanning'

ARTICLES

Sponsored Content

When producing replacement parts, 3D metrology reduces time to market and ensures quality.

Read More

Test & Inspection

The Accuracy Nexus: 3D Scanning in Additive Manufacturing for Custom Car Builds and Mesh Repair Solutions

Anyone can buy a 3D printer and set up a shop, but there are a few essential things to know — especially when it comes to mesh repair.

February 23, 2024

The Quality Show South

Podcast: Why 3D Scanning Applies to Manufacturing, Museums and Movies

February 22, 2024

Quality Headline

Hexagon’s Volume Graphics Software Wins Top Industry Award in Scanning, Metrology Category

December 20, 2023

Case Study

Hitchiner Manufacturing Overcomes Casting Challenges with Automated Blue Light 3D Scanning Technology

By implementing automation, Hitchiner increased repeatability and speed.

November 30, 2023

Test & Inspection

Advanced 3D Scanning Digitalization Technologies for NDT of Industrial Gas Turbine Components

Advanced 3D metrology software capabilities offer reliable and more efficient solutions to the limitations of conventional nondestructive methods.

August 23, 2023

Software & Analysis

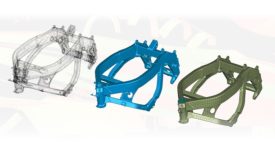

Reverse Engineering Software For 3D

Once the model has been generated, you can use the software to analyze the model.

June 6, 2023

EVENTS

Webinar

11/8/23 to 11/8/24

Contact: Meg K.

Smart 3D Measurement Planning – It’s Easier Than You Think!

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing