Home » Keywords: » force measurement

Items Tagged with 'force measurement'

ARTICLES

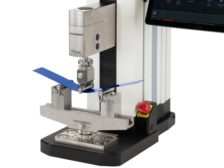

NDT | Force Measurement

How AI improves the analysis of data acquired from force measurement to prevent future product or production failures.

Read More

NDT | Compression Testing

Understanding Compression Testing and Flexural Modulus, a Crucial Aspect of Material Strength Evaluation

Advancements in materials science and engineering breakthroughs are possible through the science of compression testing.

October 6, 2023

Test & Inspection

Determining if Force and/or Material Testing is Right for your Application

Your choice can be simplified by knowing what kind of information you need to collect.

March 9, 2023

NDT | Force Testing

Measuring Force Data in Extreme Conditions

Manufacturers want more data in the product development process to create better products, and they need solutions that can perform in any condition.

February 15, 2023

NDT | Force Testing

A Case for Distance Accuracy in Force Measurement

When in doubt, specify a force tester with the tightest and most complete distance accuracy specification necessary for the application.

October 11, 2022

Test & Inspection

Navigating Supply Chain Challenges with Force Testing

Recent advancements in force measurement equipment allow quality professionals to better handle unpredictable testing demands.

May 5, 2021

NDT

Selecting and Using a Force Measurement Device

Everything you need to know.

February 15, 2021

A guide to Force Measurement in Static Materials Testing

Force testing is the most fundamental element of materials testing and continues to be critical to the safety of the world around us.

October 6, 2020

Essential Testing for Essential Industries

Force measurement is an important characteristic in meeting the requirements of a quality product.

August 26, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing