Home » Keywords: » gaging

Items Tagged with 'gaging'

ARTICLES

Measurement

Quality control is crucial for meeting high product standards, and handheld gages are key to achieving such precision. But how exactly do these tools ensure accurate measurements?

Read More

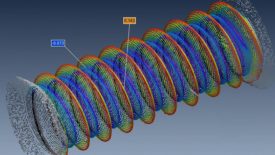

More than Laser Gages - Available Today

The added twist in recent years has been the use of a chromatic or "color" focus effect where different colors of light focus at different distances.

August 2, 2023

Measurement

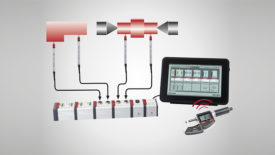

Digital Gaging: Embracing The Accessibility Afforded By Today’s Technology

Data reliability is more important than ever.

May 30, 2022

Measurement

It is Never Too Late to Teach an Old Custom Gage New Tricks

There are myriad ways to breathe new life into existing gages without the need to invest in new gaging.

March 8, 2022

Measurement

Gaging Evolves For Precision, Productivity, Ergonomics & More

Gage design is continually being enhanced and refined.

December 6, 2021

Measurement

Modern Gaging Trends: Technology Evolves to Meet the Needs of Today’s User

Implementing these new technologies will make today's gages easier to use, offer more capabilities in an easier-to-read fashion and survive point of manufacture gaging.

September 1, 2021

Measurement

Innovation is Changing the World of Handheld Gaging

Within the Manufacturing Innovation Process, Metrology has Played a Predominant Role.

July 1, 2021

Special Gage Solutions Optimize Measurement for Many Unique Applications

Discover gaging solutions for manufacturers in the automotive, aerospace, power generation, food and medical industries.

April 7, 2021

Crystal Ball Gazing: Gage Trends and Metrology

When you look at how far gages have come in just the last 20 years, you might wonder what, if any, types of technological enhancements might be on the horizon.

December 2, 2019

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing