Home » Keywords: » microscopy

Items Tagged with 'microscopy'

ARTICLES

Measurement

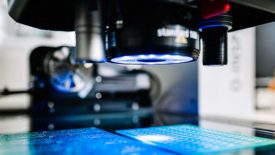

Compliance can often only be achieved through both metrology and microscopy tools.

Read More

Vision & Sensors | Lenses

Understanding the Key Factors in Microscope Objective Performance

February 6, 2024

Software

FDA-compliant results documentation with Microscopy Imaging Software

Transferring microscopy applications into production often requires validation activities.

January 11, 2024

Software & Analysis

Overcoming Quality Challenges Using AI-Powered Connected Microscopy

Integration of the latest artificial intelligence technologies enable even deeper insights.

December 28, 2023

Quality Headline

Next-Generation OEM Objectives Enable Engineers to Develop the Scientific Instruments of Tomorrow

July 18, 2022

Sponsored Content

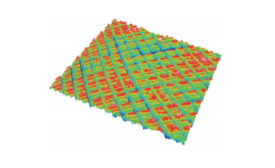

White Paper: Introduction to Surface Roughness Measurement

October 30, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing