Home » Keywords: » automotive industry

Items Tagged with 'automotive industry'

ARTICLES

Sponsored Content

Innovations at Kindig-it Design

Read More

Sponsored Content

Kindig-It Design, Can Dig It Thanks to FARO 3D Measurement Solutions

Premium Custom Car Restoration Leader

February 26, 2024

Quality Headline

US Motor Works to Build New $19M Fulfillment Center in Kansas City Metro

August 31, 2023

NDT | Additive

A Window of Opportunity to Accelerate Alloy Development for Additive Manufacturing

Opportunities for the development and validation of new tools, techniques, and methods to accelerate alloy development for AM processes do exist.

August 14, 2023

Quality Headline

Cnano Technology USA Selects Kansas City Region for North American Headquarters

August 7, 2023

Quality Headline

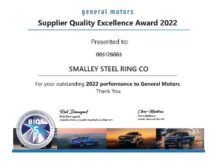

Smalley Honored with General Motors' 2022 Supplier Quality Excellence Award

July 31, 2023

NDT | XRF

Enhancing Automotive Safety With Real-Time Composition Analysis

It is crucial that the compositions of metals and alloys used in automotive fasteners are verified through stringent quality assurance.

April 14, 2023

Case Study B

Roush Yates Engines Seconds The Motion For Automated Data Acquisition

New data collection technology ensures speed, accuracy, scalability and security.

August 16, 2022

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing