Home » Keywords: » fatigue testing

Items Tagged with 'fatigue testing'

ARTICLES

Quality 101

Materials testing submits a material or product to a thorough, in-depth "check-up" to ensure overall quality.

Read More

NDT | Back 2 Basics

Methods for Cost-Effective Additive Inspection

Internal defects present the greatest lack of uncertainty and confidence when focusing on most AM parts.

September 26, 2023

NDT | Back 2 Basics

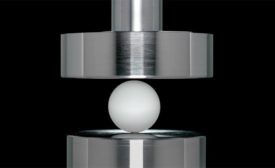

Gigacycle Fatigue Testing of Metals Using Ultrasonic Resonance

Fatigue testing is a well-known technique to help predict the long-term performance of materials.

August 15, 2023

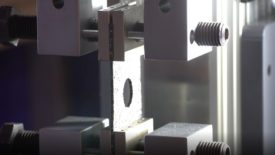

NDT | Fatigue Testing

The Future of Fatigue Testing

Newer techniques are on the rise. As manufacturing evolves, so too does fatigue testing.

June 8, 2022

NDT | Compression Testing

Squeezing the Most Out of Compression Testing

The data derived from compression testers can be helpful throughout the life cycle of a product.

August 15, 2021

NDT

Fatigue Testing 101

A brief overview of the most common types of fatigue tests and where each is commonly used.

October 1, 2019

Bearing Properties: The Impact of Residual Stress and Retained Austenite

Regardless of a bearing’s intended use, it must be designed and manufactured to withstand difficult environments.

April 1, 2019

Setting Standards for Additively Manufactured Parts

To fulfill potential, additively manufactured parts must stand up to fatigue testing.

February 1, 2018

6 Popular Fatigue Test Applications

It’s used in applications ranging from dental implants to running shoes.

August 1, 2017

Stress-Life Fatigue Testing Basics

The many variables associated with material type, sample geometry and in service use of a part or component complicates the design and implementation of an appropriate fatigue testing regime.

August 1, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing