Home » Keywords: » laser trackers

Items Tagged with 'laser trackers'

ARTICLES

Quality 101

Surf’s Up for Laser Trackers

Read More

Test & Inspection

How Laser Technology Helps Improve Manufacturing Quality

Laser technology today has taken significant leaps from even just a few years ago.

October 10, 2022

Test & Inspection

Aerospace Companies Flying High With 3D Laser Trackers

Portable metrology tools like 3D laser trackers are efficient solutions that can be implemented into aerospace workflows.

March 8, 2022

Six Ways Six Degrees of Freedom Probe Technology And Laser Trackers Can Enhance Your Business

In general 6DoF probes meet the dynamic measurement, speed, and accuracy requirements of the most challenging industrial applications.

April 7, 2021

A 'Focused' Look at Portable Precision Measurement: Understanding Laser Trackers

Laser trackers have applicability across the manufacturing lifecycle.

October 1, 2020

Quality Headline

Hexagon Announces HxGN LIVE Smart Manufacturing Detroit 2020

January 20, 2020

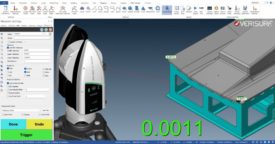

Laser Trackers Take a Bold Step into Scanning

Large scale metrology grade scanning debuts this year.

June 1, 2019

New Features, Industries Elevate Laser Trackers

A big selling point of recent iterations is seamless integration into a user’s work process.

June 1, 2019

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing