Home » Keywords: » fixturing

Items Tagged with 'fixturing'

ARTICLES

Test & Inspection

Why zero drift occurs and ways to mitigate or even eliminate it.

Read More

Case Study

Unlocking Efficiency in Education

Inspection Arsenal fixturing transforms student part inspection at Van Buren Tech in Lawrence, MI.

March 1, 2024

Test & Inspection

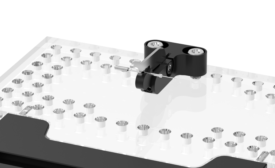

Inspection Fixturing – Not A Question Of IF!

Whether you've been tasked with designing fixtures or sourcing them for your company, there are several details to consider.

February 8, 2023

Quality 101

Fixturing 101: Crucial For Quality

Inspection data is critical to delivering perfect parts faster, experts say.

May 8, 2022

Modular Fixturing for Clay Model Making Today

Emerging autonomous vehicle companies have joined forces with automakers worldwide in designing new vehicles utilizing modular fixturing.

March 2, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing