Home » Keywords: » CMM

Items Tagged with 'CMM'

ARTICLES

Management

A Machine Trainer: Safe and efficient shop floor training management

Learn more about CNC and CMM machine trainer simulators.

October 23, 2023

Measurement

Why More Manufacturers Should Consider Implementing a Vision Measurement System

Technology advancements, emerging industries, and congressional legislation point to an exciting future for vision measurement systems.

October 18, 2023

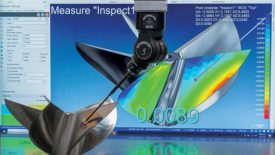

Software & Analysis

Choosing the Right Measurement and Inspection Software

January 5, 2023

Why model-based Measurement Helps Manufacturers Improve Quality

Improvements in CMM equipment and developments in model-based software solutions have also helped make the technology more accessible.

March 23, 2022

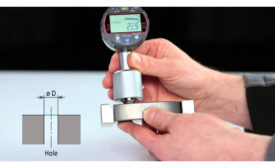

Quality 101

5 Things To Consider When Evaluating Shop-floor CMMs

As your manufacturing processes change over time, you need your quality program to keep up.

March 8, 2022

Measurement

The Future of CMMs

Although the CMM has been around for more than half a century, advancements have allowed it to maintain its position as the go-to technology for quality inspection.

November 1, 2021

Test & Inspection

Modular Tooling Keeps On Truckin’

This technology is here to stay.

September 1, 2021

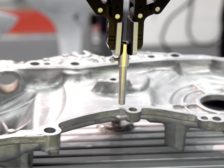

Measurement

5-Axis CMM Measurement

CMMs of the Future will Provide Immediate Feedback to Help You be Proactive When it Comes to Planning Maintenance and Workload.

June 15, 2021

EVENTS

Webinar

9/13/23 to 9/13/24

Contact: Meg M.

How to Reduce First Article Inspection Creation Time by 70-90%

Webinar

3/14/24 to 3/14/25

Contact: Meg K.

The Ride to Excellence: Embracing Digital Twins in Automotive Design, Development & Production

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing