Home » Keywords: » materials testing

Items Tagged with 'materials testing'

ARTICLES

Quality 101

Materials testing submits a material or product to a thorough, in-depth "check-up" to ensure overall quality.

Read More

From the Editor | Darryl Seland

Where Does it End? Usually Depends on Where You Start

October 26, 2023

Test & Inspection

What Product Quality Testing is Made of

Quality materials are the route to quality products.

October 19, 2023

NDT | Compression Testing

Understanding Compression Testing and Flexural Modulus, a Crucial Aspect of Material Strength Evaluation

Advancements in materials science and engineering breakthroughs are possible through the science of compression testing.

October 6, 2023

Test & Inspection

Important Considerations for Tensile Testing Equipment in Aerospace Applications

The most powerful tool a company has is the ability to follow a component failure back to the batch of material it was made from.

August 3, 2023

Quality 101

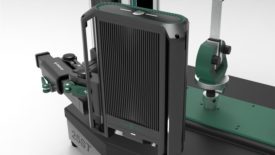

Automation in Materials Testing

There are many different parts of a universal testing machine that can be partially or fully automated depending on the specific needs of your lab.

May 15, 2023

NDT | Materials Testing

Extensometry in Materials Testing Explained

An extensometer is a device used to measure changes in the length of an object, or sample in the materials testing world.

April 11, 2023

Materials Testing

The Relationship Between Residual Stress State and Quality

Designing in, manufacturing for, and measuring residual stresses may be the most effective way to produce quality parts.

November 14, 2022

Test & Inspection

Reduce Testing Downtime through Quality Measures

Testing system downtime causes shipment delays, upset customers, and lost revenue.

August 1, 2022

Test & Inspection

A Guide to Mechanical Testing of Paper and Plastic Packaging Materials

A simple tensile test can be used as a quality control measure to ensure the materials meet internal criteria, or for comparison purposes.

July 3, 2021

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing