Aerospace

Quality Headline

America Makes Announces Third Satellite Center at NIAR on Wichita State University Campus

July 23, 2019

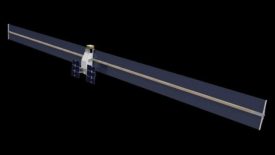

Quality Headline

Northrop Grumman to Demonstrate Robotic Manufacturing in Space

July 17, 2019

NDT in Aerospace

Compression Testing Basics

What is compression force and why do we measure it?

July 8, 2019

NDT in Aerospace

Force Gage Technology

New force gage technology offers a faster, easier alternative to conventional computer and software-based force measurement.

July 8, 2019

NDT in Aerospace

Additive Manufacturing and the Inspection Processes

It is an exciting time to be in additive manufacturing.

July 8, 2019

NDT in Aerospace

Automated Eddy Current Testing Solution for Aero-engine Discs

Eddy current testing is a crucial part of quality control.

July 8, 2019

NDT in Aerospace

Nadcap Non-Destructive Testing in Aerospace

The role of NDT is now recognized as vital to ensure the reliability of the product.

July 8, 2019

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing