Automotive

Case Study B

New data collection technology ensures speed, accuracy, scalability and security.

Read More

Management

6 Key Considerations For Applying Collaborative Robots

The extent of collaboration helps determine the need for a cobot.

June 8, 2022

Test & Inspection

Shining A Light On Color Quality Control

Monitoring color during the entire production process can help manufacturers identify color drifts before they become a problem.

March 8, 2022

Management

2022 Quality Plant of the Year: Larsen Manufacturing

Larsen Manufacturing is an industry leader in quality systems and quality assurance.

March 2, 2022

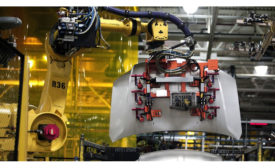

Vision & Sensors | Robotics

The Rise of Smarter Robots

Using a high-quality 3D camera, the robot can locate the part, regardless of orientation, and provide pick coordinates to the robot.

March 1, 2022

Case Study

How A Custom Crusher Used Precise Motion Data To Open New Manufacturing Possibilities

The problem wasn't whether the client could make the parts; it was whether the client could test samples in a rapid, cost-efficient, productive way.

February 15, 2022

Sponsored Content

How to Predict and Prevent Product Failure

Preventing both warranty issues and field problems due to lack of product reliability.

February 11, 2022

NDT | XRF

How to Measure Metal Coating Thickness Using Handheld X-ray Fluorescence Analyzers

Handheld XRF is an indispensable tool in quality assurance that provides multiple benefits.

February 8, 2022

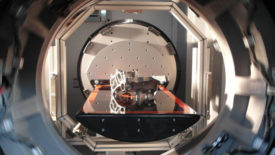

NDT | Computed Tomography

How Nondestructive Testing is Driving Sustainable Quality in the Automotive Sector

NDT techniques are available that are just as quick as destructive methods but also offer a more sustainable use of raw materials.

February 8, 2022

The Benefits of Automation

The five reasons to consider, and have been considered for decades, about automation.

December 10, 2021

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing