Quality 101

Color Measurement 101: The Basics of Managing Color throughout Production

Whenever accurate and consistent color is critical, brands and their suppliers rely on color measurement hardware.

February 15, 2019

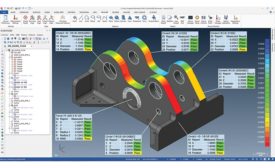

Additive Grows from Prototypes to Production Parts

Data collection and quality elevate additive manufacturing to the factory floor.

January 8, 2019

How Proper Specification of Load Cell Sensors Can Improve Force Measurement

Accuracy is only one of many characteristics that should be examined before selecting a sensor for an application.

November 8, 2018

The New Science of Laser Trackers

Today’s enabling technology for “precision anything.”

September 15, 2018

Where to Start with Ultrasonic Thickness Gaging

There are a wealth of resources for understanding the basics and newest advances in ultrasound.

August 15, 2018

Depth Gaging from Top to Bottom

A wide variety of depth gages are available for any application.

July 8, 2018

Air Gaging in a High Production, Automated Manufacturing Environment

Air gaging continues to evolve and stay relevant in today’s automated world.

May 7, 2018

Optical [Big, Bold, Fast] Metrology

Camera-based technologies are making strides in portable measurement for large surfaces.

April 2, 2018

Reverse Engineering: Outputs

Learn more about these eight options using 3D scanning.

March 6, 2018

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing