Quality 101

Quality 101

Automation: Should Manufacturers Fight Or Flight?

Despite its praised benefits, many manufacturers still decide against automation. But does that decision stem from fear?

August 16, 2022

Quality 101

Know Your True Cost of Quality with Integrated ERP

In the end, the true cost of quality comes down to the cost of making the part plus the cost of bad parts.

July 15, 2022

Quality 101

Force Testing Ensures Syringe QC During Design, Manufacture and Application

Uniaxial force testers have the advantage of performing both material tests and application demonstrations to ensure that quality products are made.

June 15, 2022

NDT | Back 2 Basics

Flaw Detection 101

Each NDT method has its advantages and disadvantages, so knowing what your flaws of interest are and where they tend to be located can be extremely helpful.

June 9, 2022

SPC’s Journey Through Time

Statistical Process Control’s impact on industry has been enormous.

June 8, 2022

Quality 101

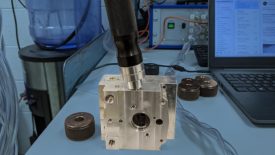

Fixturing 101: Crucial For Quality

Inspection data is critical to delivering perfect parts faster, experts say.

May 8, 2022

Why a Centralized Quality Hub Matters

A centralized quality hub should help organizations to oversee, examine, and report on data and processes from unrelated data sources in real time, creating a comprehensive vision of operations.

May 2, 2022

Quality 101

5 Things To Consider When Evaluating Shop-floor CMMs

As your manufacturing processes change over time, you need your quality program to keep up.

March 8, 2022

NDT

Quality 101: The Advanced Force Tester

Assuring Material Properties Through Material Testing

February 8, 2022

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing