Quality 101

Noncontact thickness metrology solutions have become a necessity for the manufacturing sector.

Read More

The State of Sensors in the Industrial IoT

Better quality is possible with IO-Link and machine learning.

August 8, 2019

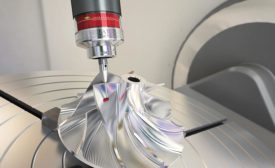

Getting Started with In-Process Gaging

Take advantage of all the benefits of in-process gaging.

July 8, 2019

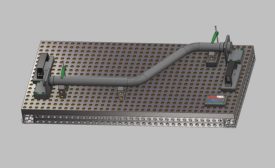

Fixturing 101: The Sky is the Limit

Fixturing tubular parts in aerospace duct fabrication with traditional vs. modular systems.

July 1, 2019

Height Gages 101

The height gage has supported the work of inspectors and machinists around the world.

May 14, 2019

Four Dangerous Myths about Quality that May Cost Lives

Important lessons from a medical devices quality veteran.

April 8, 2019

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing