Software

Software & Analysis

Metrology software is at the core of process control because it manages all the measurements and drives productivity.

Read More

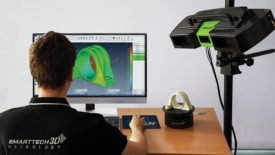

3D Scanning’s Role in Quality

As the manufacturing industry becomes more automated, quality control -- especially 3D scanners – are more key than ever.

June 9, 2022

Software & Analysis

Sledgehammer vs. Nutcracker: Which is the Right Tool for the Job?

Tools for identifying a problem, its root cause and its impact.

May 30, 2022

Software & Analysis

Manufacturers’ Top Demands For Quality Software in 2022

The bottom line is that manufacturers know they need to improve how integrated quality data is across the company.

May 8, 2022

Why Predictive Analytics Helps Boost the Bottom Line

Manufacturers use predictive maintenance software to help tie the probability of equipment breakdowns, and they can use that knowledge to schedule machine preventive maintenance and manage production.

May 6, 2022

How Quality Intelligence Platforms Help Manufacturers Predict Problems

Quality intelligence platforms and cloud-based software as a service (SaaS) models gather and analyze data to deliver insights around the manufacturing process.

April 11, 2022

Quality in Automation | Machine Learning

Bringing Quality To New Heights With Machine Learning

Five best practices for beginning the AI journey.

April 8, 2022

Software

Trends In Total Quality Management

The field of TQM software has become crowded as more vendors attempt to enter the space, experts say.

April 8, 2022

Reasons to Adopt Laser Scanning in Your Factory

In recent years, laser scanning hardware and software have improved considerably, resulting in a streamlined system that can capture vast detail rapidly.

March 22, 2022

Speaking of Quality | Heather Wilson

Quality Approaches to Software Management

Modern software applications are capable of numerious customizations, which present a unique set of challenges.

March 15, 2022

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing