Software

Manufacturers already collect data, but many can stand to optimize their processes.

Read More

Software & Analysis

Reverse Engineering Software: Who? What? When? Where? Why?

Reverse engineering is used practically everywhere and in every industry.

September 1, 2022

Vision & Sensors | Analysis

Understanding The Value Proposition For Deep Learning in Machine Vision

Deep learning software represents a powerful tool in the machine vision toolbox, but one must first understand how the technology works and where it adds value.

September 1, 2022

Case Study B

Roush Yates Engines Seconds The Motion For Automated Data Acquisition

New data collection technology ensures speed, accuracy, scalability and security.

August 16, 2022

5 Signs You May Need A Cloud-Based Quality Software Solution

Cloud based quality software has numerous benefits for manufacturers with disparate production facilities and locations.

August 8, 2022

Software & Analysis

Inspection Software Must Itself be Inspected

Software decreases the time to identify and eliminate quality risks, reuces risk-related expenses, improves compliance capacity, and optimizes labor.

August 1, 2022

How SPC Can Lead to Zero Defects

Manufacturers are already producing data. For organizations to get full value from that information, they should choose a Statistical Process Control (SPC) solution that configures notifications, automatic alarms, emails, and process alerts.

July 12, 2022

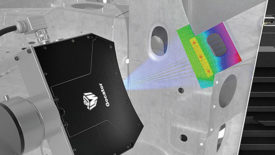

Vision & Sensors | System Integration

The Power Of Embedded GPU-Driven Smart Sensor Acceleration

There are four common reasons manufacturers would need to use a smart vision accelerator to enhance the inspection performance of their sensor.

July 6, 2022

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing