Measurement

Measurement

Confocal chromatic measuring systems provide highly accurate distance, position, displacement and thickness measurements.

Read More

From the Editor | Darryl Seland

Consolidation: One-Stop-Shops and All-in-One Computers

June 15, 2022

Measurement

Digital Gaging: Embracing The Accessibility Afforded By Today’s Technology

Data reliability is more important than ever.

May 30, 2022

Test & Inspection

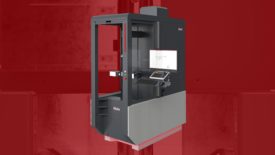

Is it Possible to Measure Shaft, Form and Gear with an All-In-One Machine?

Do more with less — minimizing downtime for production workpiece measurements.

May 30, 2022

Face of Quality | Jim L. Smith

Quality Professionals Must Lead

Communicate the economic case for quality.

May 15, 2022

What Is a Digital Twin?

Digital twin technology helps organizations to use real-time data, mockups, algorithms, and AI to create a virtual depiction of a physical object, process, or service.

May 9, 2022

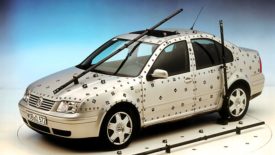

In-line Inspection with CMMs

By increasing the frequency of inspections and decreasing the time of inspection throughout the production process, inspecting in or near the production line allows for verification of 100% of components.

May 3, 2022

Test & Inspection

Measurement And Inspection Standards

As technology continues to evolve, it will take a lot of work from the standards community to help the industry keep pace with news tools for new manufacturing methods.

May 1, 2022

Measurement

What is Uncertainty? In Metrology, It’s Truly a Deep, Sensitive Subject

May 1, 2022

Quality 101: The World Of Indicators

As they have advanced over the years, the initial concept of the indicator still holds true: a need to measure small measurements and angles.

April 15, 2022

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing