Measurement

Measurement

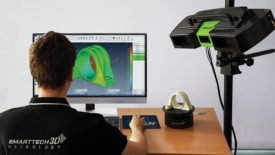

When are non-contact structured light 3D scanners better suited than touch CMMs?

Read More

Measurement

Handheld Gaging: It All Comes Down To The Touch

Combining the best of metrology and other industries creates products that are simple for the operator to use while also providing very complex measuring results.

September 1, 2022

Case Study B

Roush Yates Engines Seconds The Motion For Automated Data Acquisition

New data collection technology ensures speed, accuracy, scalability and security.

August 16, 2022

Case Study

Miltera Achieves Success with ZEISS Industrial Quality Solutions

Miltera has built up a reputation as a specialist in producing everything from racecar parts to mold components, consumer electronics, turbine compressors and turbochargers for the aerospace industry.

August 16, 2022

Face of Quality | Jim L. Smith

Tips for Success, Part 2

Focus on the important actions to improve performance.

August 15, 2022

Measurement

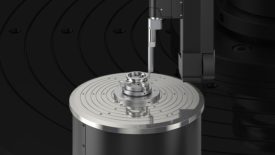

Roundness Measurement Technology Drives Quality and Productivity

For certain parts and products, roundness measurement is a critical part of the quality assurance process.

August 1, 2022

Face of Quality | Jim L. Smith

Tips for Success, Part 1

Organizations should focus on important actions.

July 15, 2022

Test & Inspection: Measuring Magnetic Properties

Measuring magnetic properties can determine the effect of heat treatment on a material

July 8, 2022

Today’s CMMs Are Known for Adaptability, Ease of Use

As the skills gap continues to impact the manufacturing field, skilled CMM users and programmers are harder to come by. In response, CMM companies have built the tools to be easier to operate and program.

July 8, 2022

Software & Analysis

Automating Scan-Based Inspection for Repeatable Process Control

Metrology software is at the core of process control because it manages all the measurements and drives productivity.

July 1, 2022

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing